Carburizing of Large Gears – Haerterei Reese

Carburizing of large gears has been much in the news recently due to the closing in the USA of commercial heat treater Metlab who offered the largest commercially available pit carburizing furnaces in North America (https://themonty.com/metlab-ht-closing-giving-gear-suppliers-headaches/) As you can...

KGO, Wetter, Germany

During a visit to a number of heat treat industry suppliers and heat treaters in Germany, Gord and Jordan Montgomery of "The Monty Heat Treat News" took the opportunity to visit a well known furnace builder in Wetter, Germany by the name of "KGO". At this point we should probably correct what we...

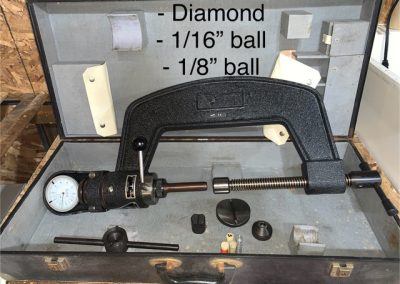

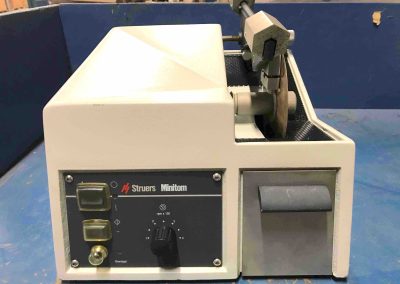

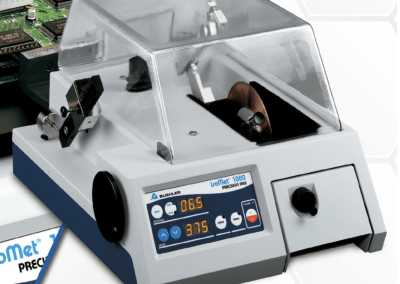

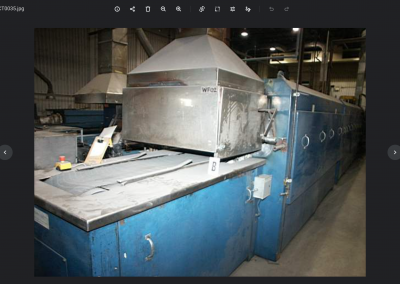

Used Furnace And Equipment Listings

“The Monty” has one of the largest listings for used heat treating equipment in North America. Below you will find our two most recent additions and also a categorized listing by furnace type. If you don’t find what you are looking for let us know and we will find it for you. Have equipment to sell? We are here to find you a buyer, just drop a line to [email protected]

Ipsen Customer Service (ICS) Team Expands to Support Growing Aftermarket Needs

Ipsen bolsters its aftermarket team with the addition of two new Regional Sales Engineers. Tyler Free will support customers in the Midwest, while Charlie Preston will serve the Southeast region. They join a seasoned team, including Steve Mondorf (West), Tom Sutherland (South), and Chad Mehmel...

Automotive Company Orders Second EndoFlex Generator From UPC-Marathon, a Nitrex Company

"An automotive company in South America has recently placed a follow-up order for a second EndoFlex generator from UPC-Marathon, a Nitrex company. Following the successful installation of a 200 m³/h EndoFlex unit last year, the new generator, boasting a similar capacity, aims to enhance stability,...

SSi Mexico

Recently Jordan and Gord Montgomery of "The Monty Heat Treat News" attended the ASM 2024 Heat Treat exhibition in Queretaro, Mexico during which time they were able to visit a number of in house and commercial heat treaters in area. For many of these visits their hosts were the local SSi team-they...

German Fastener Manufacturer Adds Mesh Belt Furnace Line

Today (April 22, 2024) "The Monty" was able to visit a large German manufacturer of automotive and aerospace fasteners. What made this visit very memorable was that the company is just days away from starting up a brand new mesh belt furnace line with a capacity of 1,000 kg/hour (2,200 pounds). ...

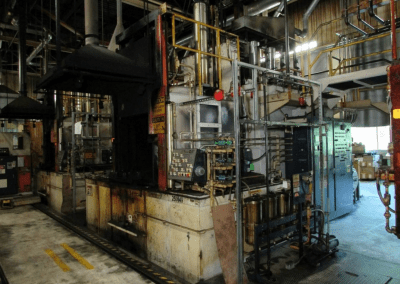

“The Monty” Visits “Top 11” Captive Heat Treater

For a number of years now "The Monty Heat Treat News" has been putting together an annual list of the "Top 11 Captive Heat Treaters in North America". This list includes what we believe to be the 11 largest single location captive heat treaters in North America. One that we visited last week in...

European Manufacturer Adds Nitriding System

"Kuźnia Jawor S.A., a European company specializing in the production of hot forged and CNC machined components for the automotive, machinery, mining, and piping industries, has enhanced its manufacturing capabilities through a substantial plant modernization. Located in the southwestern region of...

US Heat Treat Fire Blamed on Foreign Sabotage?

In almost 30 years of reporting news about the global heat treatment industry "The Monty Heat Treat News" has reported on many fires and whenever possible the cause. However this is the first time we have run across a fire in a heat treat department possibly being blamed on foreign sabotage-read on...

Michigan, USA Fastener Manufacturer to Install 3 Mesh Belt Lines?

Earlier this year "The Monty Heat Treat News" had a news item about a Turkish company by the name of Norm Fasteners investing in a new fastener manufacturing facility in Lansing, Michigan. The original news item can be found below and as our readers can see we mentioned at the time that it would...

Metlab HT Closing Giving Gear Suppliers “Headaches”

The recent closing of commercial heat treater "Metlab Heat Treat in Wyndmoor, PA, USA (the original news release can be found below) has had lasting ramifications on the gear industry in North America-let us explain. Metlab in size we would have considered to be "average" in terms of annual sales...

Crio, Mexico Top 5 Mexican Heat Treat

It has been 4 years since “The Monty Heat Treat News” visited commercial heat treater “Crio” ( https://www.criomx.com/ws/services.html) in Querétaro, Mexico and we welcomed the opportunity for another visit last week. What we found was a company which has invested heavily since then both in terms of...

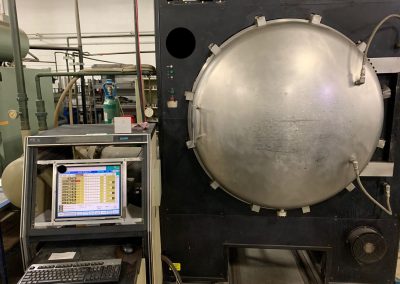

Aerospace Company Completes Expansion Which Includes Vacuum Brazing

Aerospace company Barnes has just completed the expansion of a new facility in East Granby, Connecticut, USA. This facility boasts several vacuum brazing systems. "BRISTOL, Conn.--(BUSINESS WIRE)-- Barnes Aerospace proudly announces the completion of its newly expanded Maintenance, Repair, and...

Aerospace Heat Treating-Safran Group S.A.

Querétaro, Mexico, April 12, 2024; Safran S.A., is a French multinational aerospace and defense corporation that designs, develops and manufactures aircraft engines, helicopter engines, spacecraft propulsion systems as well as various other aerospace and military...